What Is a Scaffolding Coupler?

A scaffolding coupler is a mechanical device used to connect two or more scaffold tubes together securely. Think of it as the “link” that holds your scaffold structure firm and stable. Couplers are essential for creating safe work platforms, supporting heavy loads, and ensuring construction sites meet safety standards. Without them, scaffolding could collapse under stress, putting workers at risk.

Why Choosing the Right Coupler Matters

Selecting the right coupler isn’t just about fitting pieces together—it’s about safety, durability, and efficiency. The correct coupler ensures:

- Load handling: Supports the weight of workers, materials, and equipment.

- Structural stability: Maintains scaffold integrity under stress.

- Safety compliance: Meets construction and safety regulations to prevent accidents.

Using an unsuitable coupler can compromise the entire scaffolding structure, so understanding each type’s use is crucial.

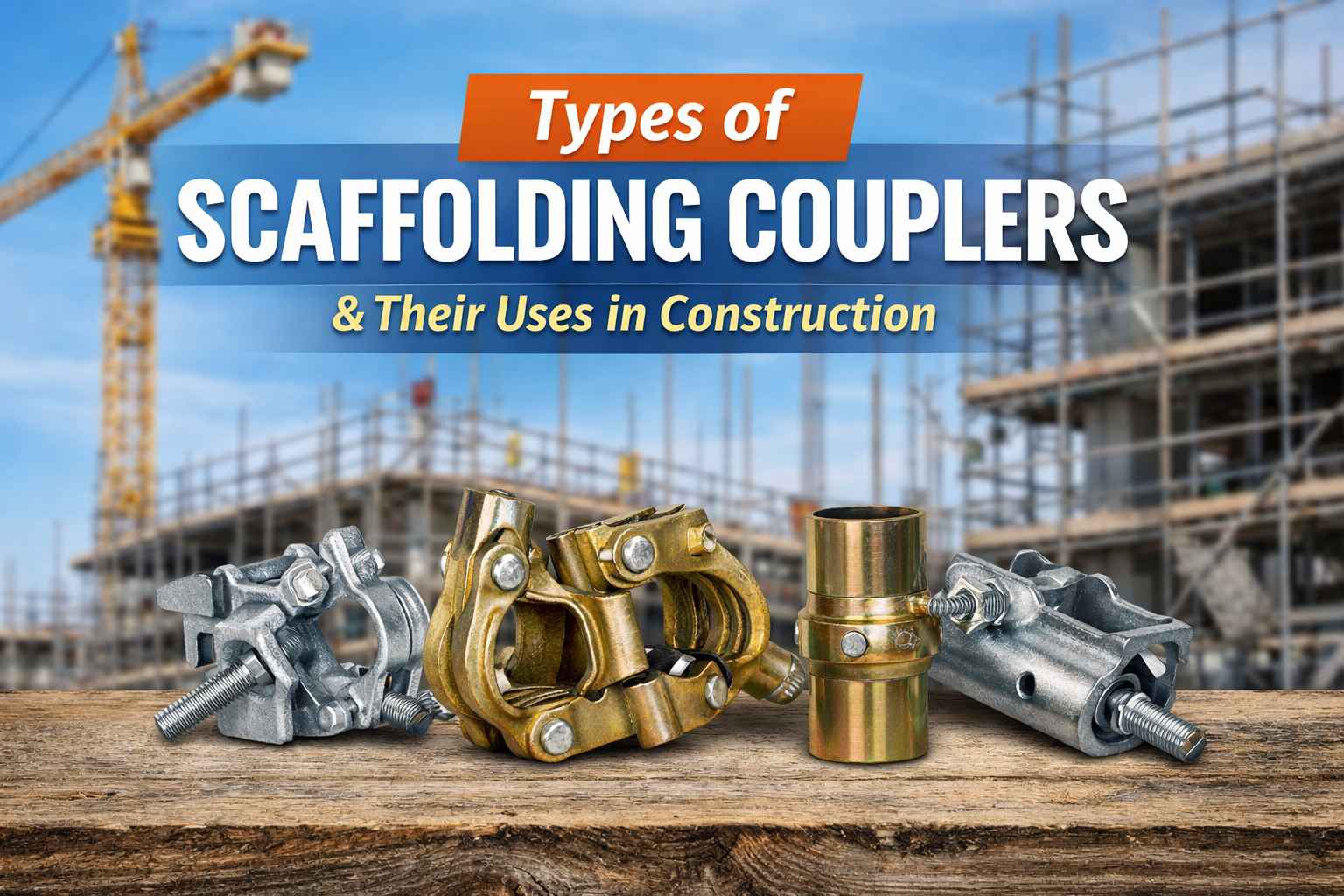

Main Types of Scaffolding Couplers

-

Double (Right-Angle) Coupler

Connects two scaffold tubes at 90 degrees, commonly used for ledgers to standards. Use case: Vertical and horizontal connections. Application: Tube-to-tube junctions in platforms, handrails, and safety barriers.

-

Swivel Coupler

Allows tubes to connect at any angle for complex scaffolds. Use case: Irregular structures, curved scaffolds. Application: Bridge scaffolds, circular staircases.

-

Sleeve Coupler / Coupling Pin

Joins two tubes end-to-end to extend scaffolds. Use case: Vertical/horizontal extensions. Application: Long walls, tall frameworks.

-

Putlog Coupler

Secures putlogs to ledgers or walls. Use case: Wall tie-ins. Application: Masonry scaffolds, wall-supporting platforms.

-

Girder Coupler

Attaches tubes to steel beams or girders for heavy-duty scaffolding. Use case: Industrial/commercial projects. Application: Bridges, large halls, factory frameworks.

-

Board Retaining Coupler

Holds scaffold boards to prevent slipping. Use case: Worker safety on platforms. Application: Platforms, walkways, temporary stages.

Which Scaffolding Coupler Is Best for Your Project?

Choosing the right coupler depends on scaffold type, load requirements, flexibility needed, and compliance needs. For guidance on selecting the correct couplers and clamps, check 👉 scaffolding couplers and clamps.

Safety Standards for Scaffolding Couplers

- Load Ratings: Follow manufacturer weight limits to prevent failures.

- Inspection & Maintenance: Check for cracks, corrosion, or worn threads; bolts should tighten smoothly.

- Compliance: Follow OSHA or international safety guidelines.

Common mistakes to avoid include wrong coupler type, overloading, neglecting inspections, and improper tightening of bolts.

Tips for Choosing Quality Couplers

- Opt for certified, high-quality steel couplers.

- Ensure corrosion-resistant finishes for outdoor use.

- Verify manufacturer load ratings and compliance.

- Use only compatible couplers for your scaffold tubes.

Benefits of Using the Right Coupler

- Enhanced safety: Minimizes accident risks.

- Structural integrity: Reduces chances of collapse.

- Efficiency: Speeds assembly and disassembly.

- Cost-effectiveness: Lowers maintenance and replacement costs.

Conclusion

Understanding scaffolding coupler types and their proper use is vital for construction safety and efficiency. Right-angle, swivel, sleeve, putlog, girder, and board retaining couplers each serve unique purposes. Selecting the correct coupler ensures your scaffold is strong, safe, and compliant. For high-quality couplers and clamps, visit 👉 scaffolding couplers and clamps.

FAQs

The double (right-angle) coupler is most commonly used in standard scaffolding setups.

Yes, swivel couplers can hold substantial weight, but always check manufacturer load ratings.

Inspect couplers before every major project or at least monthly for long-term scaffolds.

No, always ensure the coupler size matches your tube diameter.

It allows tubes to attach securely to steel beams, providing strong support for heavy scaffolds.